FACE RECOGNITION + Temperature Measurement sensor

Face Recognition Terminal and non-contact temperature measurement. Device can be used at offices, factories, warehouses, airports and subways, other public places

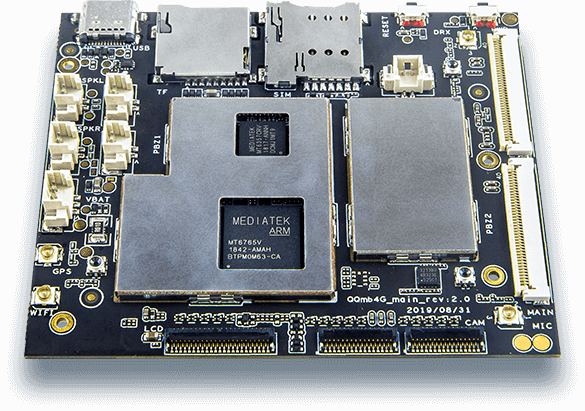

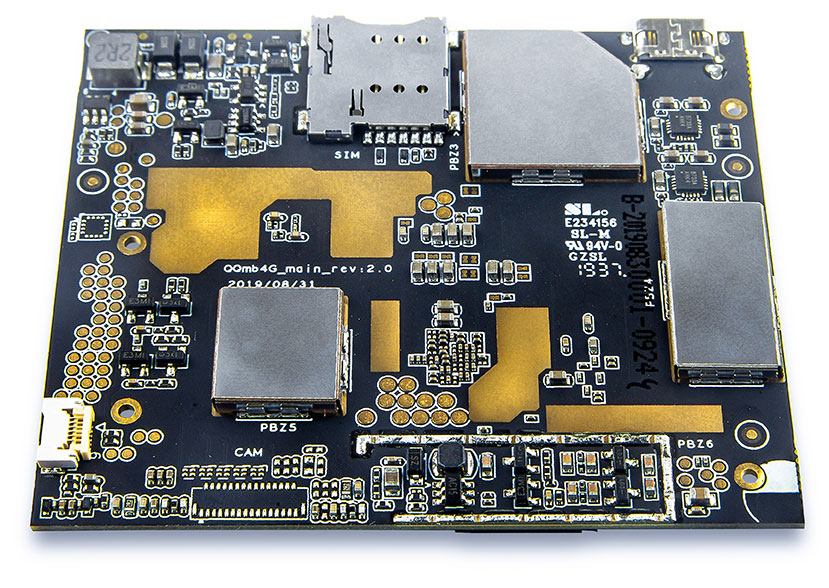

Hardware

•Mediatek MT6762, 2GB RAM, 16GB Flash

•IMG PowerVR GE8320

•7-inch TFT IPS with touch panel

•LTE/3G/EDGE connectivity

•WIFI 802.11 ac/a/b/g/n

•Bluetooth 5.0

•Dual SIM, SD card

•GPS/Glonass/Beidou/Galileo

•USB type С 2.0, OTG , speakers, mic

•Dual camera 2MP/2MP, IR LED

Software

•Android 8.1 with hardware drivers

•Firmware with user app pre-installed

•OTA , MDM

Optional

Temperature measurement sensor

•Mediatek MT6762, 2GB RAM, 16GB Flash

•IMG PowerVR GE8320

•7-inch TFT IPS with touch panel

•LTE/3G/EDGE connectivity

•WIFI 802.11 ac/a/b/g/n

•Bluetooth 5.0

•Dual SIM, SD card

•GPS/Glonass/Beidou/Galileo

•USB type С 2.0, OTG , speakers, mic

•Dual camera 2MP/2MP, IR LED

Software

•Android 8.1 with hardware drivers

•Firmware with user app pre-installed

•OTA , MDM

Optional

Temperature measurement sensor

Electronic and Industrial Design, Manufacturing in THE Asian region

We provide low-cost development of electronic products and we are extensive experienced in mass production

Contact to us

Leave your contacts and question

By clicking on the button, you consent to the processing of personal data and agree to the privacy policy

Our experience and skills

We have the in-house skills and experience to develop Embedded Solutions, Connected IoT Devices and Industrial Equipment

Industrial Design

The look and feel is a key factor in the commercial success of your product, and every design starts with end-user research

Mechanical

The mechanical design is the device's spine and must be both simple and strong

Electronics

The art of electronic engineers is to find the balance between performance, cost and reliability

MCU Firmware

To make our firmware efficient we focus on the accuracy of algorithms, simplicity and the conciseness of code, we never stop testing

Cloud

Cloud software takes your solution to the highest level of usability and functionality

Android Firmware

AOSP Android is good, but it can be so much better with individual Android firmware adapted to the specific solution

Easy and Fast product manufacturing with our QQmb platform

Using a standard hardware platform and components allows our customers to manufacture products at incredible speed

STEP 1

Choose QQmb 3G or 4G and standard components (displays, cameras and others)

STEP 2

Let us make an extension board and unique case design for you

STEP 3

Make a prototype and check functionality

STEP 4

We will organize all the processes necessary to start mass production

1 week

1 month

1-2 month

1-2 month

We create products based on the best solutions from the TOP VENDORS

Our in-house team of electronic engineers has wide experience in developing products based on embedded solutions such as STM32, PIC32, Espressif,

Maxim Integrated and others

Maxim Integrated and others

Transparent scope and time management

Schematics

Product

presentation

presentation

Functional

prototype

prototype

Pilot

samples

samples

Beta testing run

Mass production

Enclosure

Firmware

Software

Documentation

Accessories

•ID render

•Detailed specification

•Structural diagram

•Cost estimation

•Detailed specification

•Structural diagram

•Cost estimation

•3D printed enclosure

•PCBA or DevKit

•Minimal SW

•PCBA or DevKit

•Minimal SW

•T0 enclosure

•PCBA

•MVP SW

•PCBA

•MVP SW

•Fully functional units for beta testing

•White box packaging

•White box packaging

•Fully functional units, all accessories, printing and packaging

•Technical support required

•Technical support required

Visible milestones for project reporting, a progress bar for each project flow, actual and an evolving scope, timely updates and online approval process

2-4 month

1-3 month

1 month

1-2 month

MASS ELECTRONICS MANUFACTURING IN CHINA

PROCUREMENTs

Cooperation with global suppliers and direct purchasing PCB, displays, touch panels, connectors and many other components

Quality

Inspecting the quality of the development and production processes at all stages is one of our key values

LogistiCS

Whether you ship your goods by sea, air, rail, FOB, DDP or EXW, you get the finished product on the best conditions using our logistics service

SMT

The organization of auxiliary and related technological processes is as important as the SMT process

AssemblY

Assembly lines equipped with a professional team and tools are controlled by the manufacturing enterprise system (MES)

WarRanty/Certification

FCC, CE, IC, E-mark, PTCRB, RICH, EAC and others, - our experts and engineers are fully cinversant with all types of certification

Why TOP-RANKED COMPANIES TRUST Dannie

- Open BOMWe suggest the open BOM concept to our best customers t. It allows us both to receive low costs and stable profits

- business and development process transparencyWe provide a detailed project plan and schedule to our clients and report on the project status weekly

- Professional teamOur company is our people. Dannie has highly qualified experts in such areas as software, firmware, circuit design and industrial design.

About Us

Dannie provides an electronics ODM service for B2B and B2C companies. We offer our customers a complete life-cycle service starting with the design, and going right through to after-sales support. We focus on connected embedded electronics solutions.

Officies

Contact Us

Please contact us for further information

Email: info@dannie.hk

Email: info@dannie.hk